VOLTERA

Stop waiting. Start iterating.

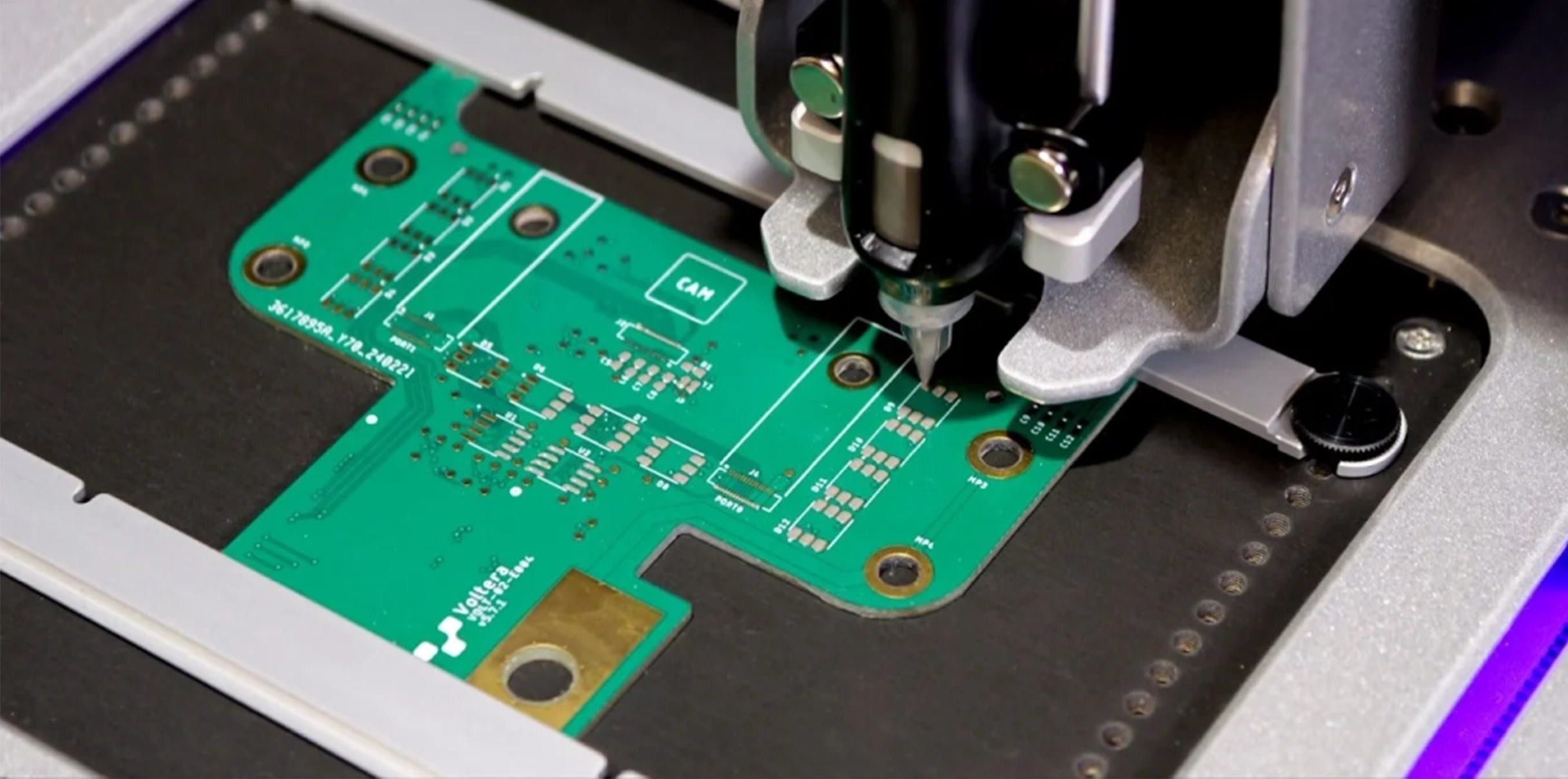

Voltera puts additive prototyping in your hands. Build traditional circuit boards or flexible, stretchable, and conformable electronics quickly and easily without leaving your workspace.

Trusted by innovators

We're fixing what's broken in electronics prototyping

Prototyping electronics is way harder than it should be. You can send off your files and wait days or weeks for something that might not even work.

Our benchtop printers put prototyping/manufacturing back in your hands. Whether you're working on rigid circuit boards, experimenting with flexible, stretchable, or conformable designs, or dispensing novel materials, they allow you to iterate, refine, and test your circuit designs or ink formulations within hours.

That's why teams at leading institutions and companies worldwide trust our products to take them from design to prototype.

We're fixing what's broken in electronics prototyping

Prototyping electronics is way harder than it should be. You can send off your files and wait days or weeks for something that might not even work.

Our benchtop printers put prototyping/manufacturing back in your hands. Whether you're working on rigid circuit boards, experimenting with flexible, stretchable, or conformable designs, or dispensing novel materials, they allow you to iterate, refine, and test your circuit designs or ink formulations within hours.

That's why teams at leading institutions and companies worldwide trust our products to take them from design to prototype.

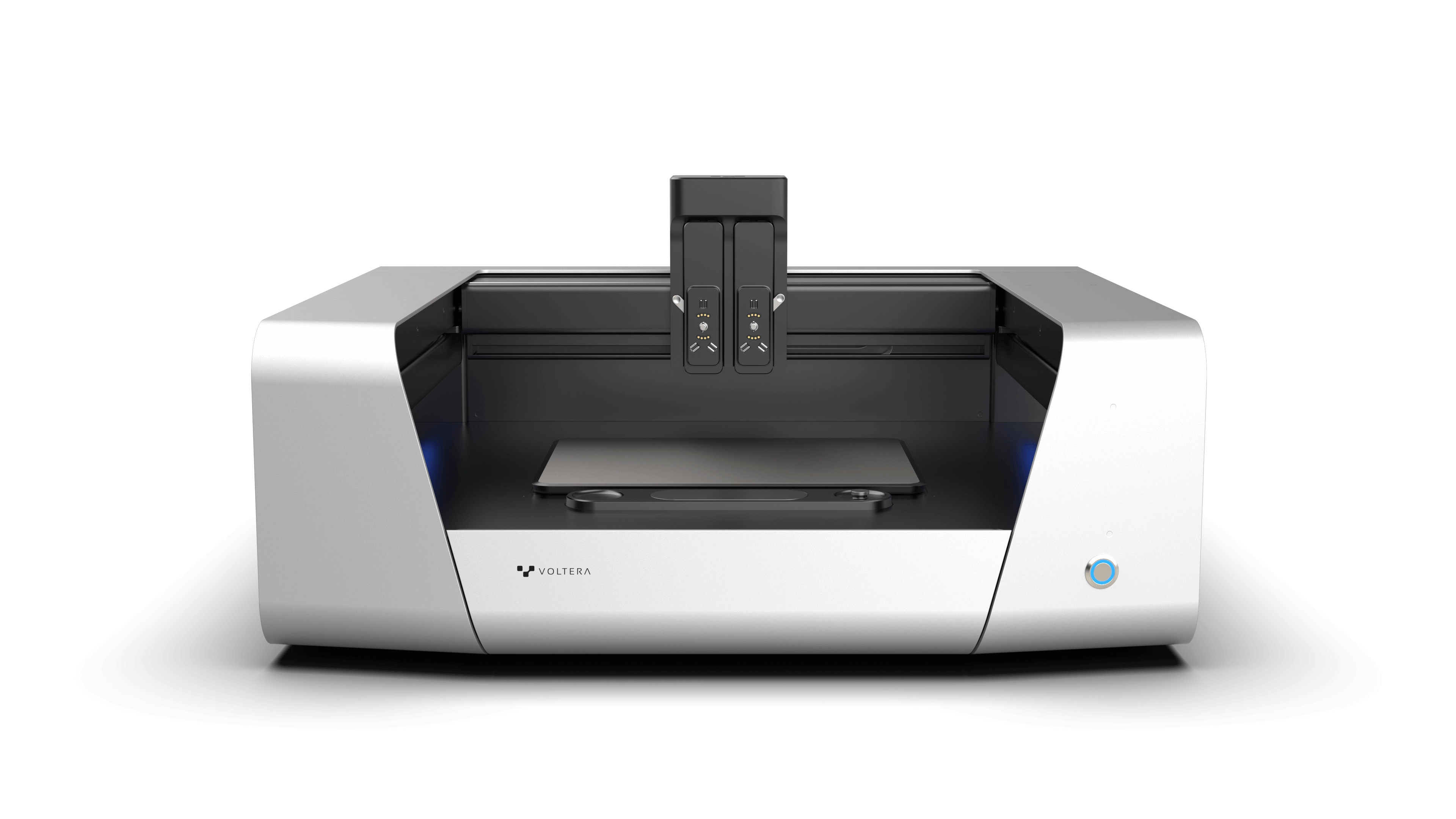

Our dispensing systems for electronics prototyping

V-One

Turn your PCB design into a prototype in hours, not days.

Ideal for:

- ✓PCB prototyping

- ✓Hands-on learning

- ✓PCB assembly

- ✓Makerspaces

NOVA

Push the boundaries of what's possible in electronics and material science.

Ideal for:

- ✓Printed electronics R&D

- ✓Flexible and stretchable electronics

- ✓Microdispensing

- ✓Functional materials research

Easy to learn, easy to use

Our printers are designed for ease of use, with a simple interface and software that makes getting started easier – whether you're a high school student or a rocket scientist.

If you need help, our support team and resources are right there with you. You won't be stuck fighting with complex setups or confusing processes – just the tools you've been searching for.

Easy to learn, easy to use

Our printers are designed for ease of use, with a simple interface and software that makes getting started easier – whether you're a high school student or a rocket scientist.

If you need help, our support team and resources are right there with you. You won't be stuck fighting with complex setups or confusing processes – just the tools you've been searching for.

How we're changing electronics

Unlocking new possibilities

The future of electronics will be cost-effective, lightweight, bendable, and integrated into structures. Our dispensing systems unlock these possibilities for a competitive advantage.

Enabling materials freedom

Additive technology offers materials freedom – for inks and substrates – creating new applications in wearable electronics, biomedical devices, printed sensors, and more.

Increasing iteration efficiency

Digital, additive prototyping is faster than alternative methods – iterate designs without investing in or waiting for tooling, reducing costs and accelerating design outcomes.

Removing barriers

No contract manufacturers, no minimum order quantity, lower cost of entry, easier-to-use machines, and design freedom. Additive prototyping solves problems you didn't even know you had.

Protecting your IP

Prototyping and iterating in-house means your designs stay yours. There's no need to share files or sensitive information with third parties during design and proof of concept phases. Safeguard your IP and maintain control over your process.

Reducing waste

Additive manufacturing isn't just faster, it's more sustainable. By reducing material waste, avoiding hazardous processes, and minimizing shipping needs, Voltera's tools help you prototype greener.

Not sure which materials work together?

Choosing the right ink and substrate, especially for flexible hybrid electronics, can be tricky. Our compatibility guide breaks it down so you can make the best choice for your next project.

Not sure which materials work together?

Choosing the right ink and substrate, especially for flexible hybrid electronics, can be tricky. Our compatibility guide breaks it down so you can make the best choice for your next project.

Additive electronics use cases

Flexible membrane keyboard

Flexible PCBs open up new possibilities for electronics design, offering lightweight, adaptable solutions for applications like membrane keyboards in medical devices and industrial controls. These circuits combine duribility with flexibility, making them ideal for compact and demanding environments.

Using NOVA, we demonstrated how to print a flexible circuit on PET film with silver conductive ink, showcasing a streamlined approach to prototyping and iteration. By eliminating the need for expensive tool or outsourcing, this process empowers engineers and researchers to refine designs in-house with precision and speed.

Materials and process

- Ink: ACI SS1109 Stretchable Silver Ink

- Curing: 5 minutes at 135°C

- Ink: ACI SS1109 Stretchable Silver Ink

- Curing: 5 minutes at 135°C

- Ink: ACI SS1109 Stretchable Silver Ink

- Curing: 5 minutes at 135°C

Flexible membrane keyboard

Electroluminescent logo

Magnesium zinc battery

Prototype on your own terms

Move faster, experiment freely, and bring your ideas to life with Voltera.

Prototype on your own terms

Move faster, experiment freely, and bring your ideas to life with Voltera.

Sign up for our newsletter

Voltera's monthly newsletter on what we're building, blogging, and brainstorming.