Researching Printed Stretchable Bioelectronics with Voltera NOVA and V-One

INDUSTRY

Academia, Healthcare, Sensors, Sustainability, Wearables

APPLICATION

Bioelectronics

PRODUCT

V-One and NOVA

Highlights

Professor Fabio Cicoira and his team at Polytechnique Montréal are experts in chemical engineering, materials science, electrochemistry, and advanced manufacturing. They purchased a V-One PCB printer for their lab in 2020, and were one of the very first customers to purchase a NOVA material dispensing system when it was released in 2022.

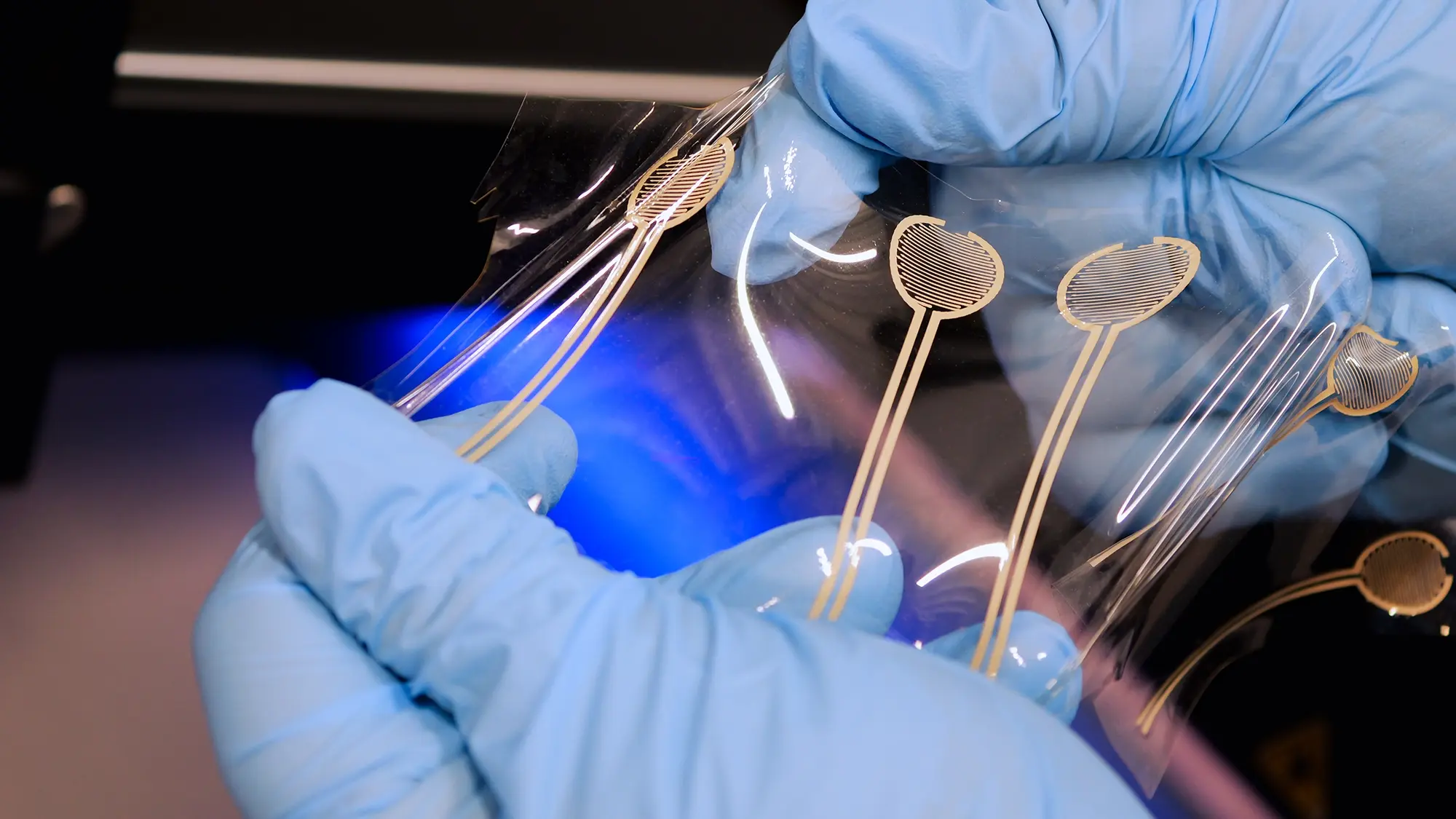

Their research focuses on polymer poly(3,4) ethylenedioxythiophene doped with polystyrene sulfonate (PEDOT:PSS), a self-healing thin film polymer, and its applications in organic bioelectronics, flexible, and stretchable electronics, as well as organic and inorganic ion-gated transistors.

“It goes without saying that it’s much easier to print our designs with NOVA, and the results are also precise. We can print everything with NOVA in one day, as opposed to making stencils one-by-one with screen printing.”

— Fabio Cicoira, Professor of Chemical Engineering at Polytechnique Montréal

Printing wearable bioelectronics with V-One

In recent years, Professor Cicoira and his team have used V-One to study conductive polymer materials and their application in stretchable, flexible, and recyclable electronic devices, such as electrocardiogram (ECG) electrodes, pressure sensors, and organic electrochemical transistors (OECTs). Some of their latest publications include:

- Self-Healing, Stretchable and Recyclable Polyurethane-PEDOT:PSS Conductive Blends (2024, Jinsil Kim et al)

- Printable, Adhesive, and Self-Healing Dry Epidermal Electrodes Based on PEDOT: PSS and Polyurethane Diol (2023, Pierre Kateb et al)

- All-Printed and Stretchable Organic Electrochemical Transistors Using a Hydrogel Electrolyte (2023, Chi-Hyeong Kim et al)

- Flexible and Stretchable Printed Conducting Polymer Devices for Electrodermal Activity Measurements (2022, Jo'Elen Hagler et al)

- Combining Electrospinning and Electrode Printing for the Fabrication of Stretchable Organic Electrochemical Transistors (2021, Michael Lerond et al)

- … And more.

While the team has achieved success printing on flexible substrates such as thermoplastic polyurethane (TPU), it became apparent that NOVA would provide more benefits in precise dispensing of materials on flexible substrates.

Leveling up with NOVA

Professor Cicoira and his students are happy with the impact NOVA has had on their research. For Jiaxin Fan, a postdoctoral fellow focusing on wearable biosensors for medical and biological applications and printed electronics, two significant improvements with NOVA have been the ease of aligning patterns and traces, as well as the pressure sensor's ability to provide a steady flow and produce reliable print results.

“One thing that really stands out about NOVA is the multilayer printing capability and the integrated computer vision. With the camera, we can align the patterns much more easily compared to V-One. This is particularly relevant, for example, when a student prints conductive polymers on top of gold electrodes and needs to achieve accurate alignment.”

— Jiaxin Fan, Postdoctoral Fellow, Laboratory of Organic Iontronics at Polytechnique Montréal

For Chi-hyeong Kim, a PhD student in Chemical Engineering at Polytechnique Montréal, researching stretchable bioelectronics for biomedical applications, learning to use NOVA and teaching it to other students was straightforward thanks to the video tutorial embedded in NOVA’s software. NOVA also enabled him to print less viscous materials, such as gallium-based liquid metal ink with an organic suspension.

“Sometimes when I train someone who wants to use NOVA, it only takes a few minutes to teach them how to use it, because the steps are easy and there are on-screen instructions.”

— Chi-hyeong Kim, a PhD student in Chemical Engineering at Polytechnique Montréal

Also helpful for the team is NOVA’s large print area (220 mm × 300 mm), which saves them time by eliminating the need to change and secure the substrate, and then regenerate the height map.

Since becoming a Voltera customer, Professor Cicoira has recommended Voltera printers to several colleagues due to their precision and ease of use. As his team progresses their research using V-One and NOVA, we look forward to seeing the new and exciting ways they innovate in the fields of flexible, stretchable, and healable electronics, patterning and processing of organic electronic materials, electrochemical transistors, implantable electrodes, organic field-effect transistors, and organic thin film growth.

Additional resources:

Want to learn more about our printers?

Learn how a Voltera dispensing system can help you prototype faster, waste less material, and protect your intellectual property.