Empowering Space Exploration with Voltera’s V-One PCB Printer

INDUSTRY

Academia, Aerospace, Defense

APPLICATION

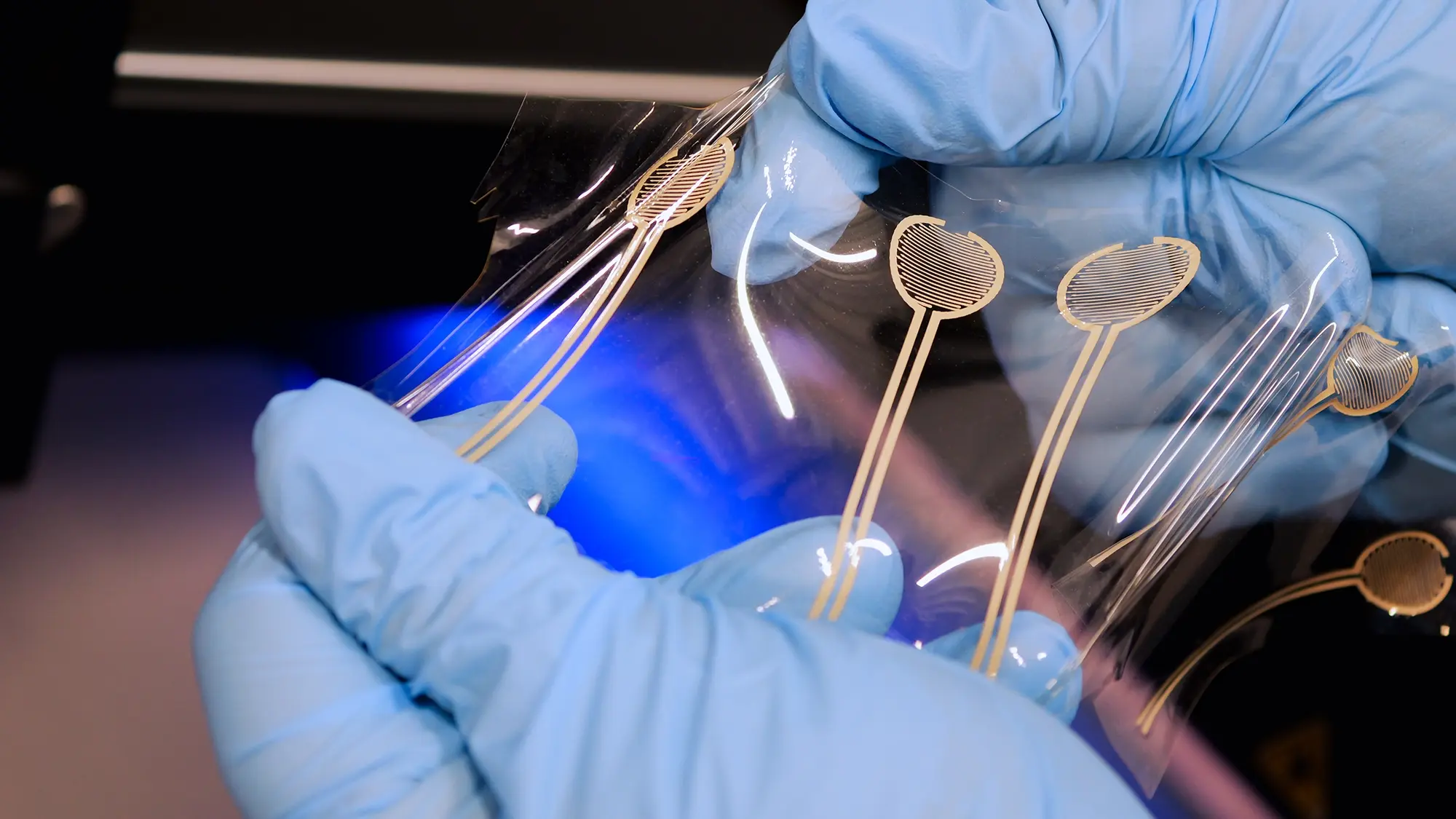

Additive PCB Prototyping, Printed Antennas, Solder Paste Dispensing

PRODUCT

V-One

Highlights

The vastness of space provides seemingly endless opportunities for exploration and innovation. It’s what is at the forefront of the mechanical and aerospace engineer program at Princeton University. Mechanical and aerospace engineering students are using Voltera’s V-One PCB printer to build CubeSats, miniature satellites that are designed for space research.

V-One: Enabling innovation

When Mike Galvin, Sr. Technical Support, Mechanical Engineer, at Princeton started building out a design lab, he wanted to focus on enabling students to make every piece of the spacecraft in-house, on the grounds of Princeton University. It was important to him that they see their work through from build to launch during their undergrad tenure.

For student Shannen Prindle, hands-on experience with V-One meant a deeper understanding of the project. From conceptualization to launch, she was involved in every aspect of spacecraft’s development — including the rapid prototyping and fabrication of the project’s printed circuit boards. Using V-One meant that Shannen and her peers gained insightful knowledge on the electronic circuitry involved in such a complex project.

“If we didn't have something like the Voltera V-One (...) I don't think I would fully understand what goes into a circuit. Being able to see where the electronics go helped me understand what components go where.”- Shannen Prindle, Student at Princeton University

V-One was designed to have a user-friendly interface, which means it’s easy to use — for novices and, in the case of Princeton University, students. Enhancing a student’s understanding of the process, from the design of the PCB to the placement of components, means there is also a deeper understanding of what is required to ensure a project with the size and scope of this one — launching a spacecraft into orbit — will be successful.

“Before they graduate, (students) can see a small spacecraft through from conceptual design, through preliminary design review, detail design, integration, build, fabrication all the way through spacecraft qualification tests, integration for launch, and then finally orbital launch.”- Mike Galvin, Sr. Technical Support, Mechanical Engineer, at Princeton University

Infinite possibilities

Using V-One to teach electronics gives students the hands-on experience they need to learn. What starts as a simple idea evolves over time to become a well thought out project plan. With very minimal training and user-friendly software, V-One will be up and running and students will be designing and printing PCBs in a matter of hours.

Adding a V-One to their lab bench means that students at Princeton University could validate experiments and gain practical intuition that they wouldn’t get by outsourcing fabrication.

Additional resources

- Princeton University TigerSats: Design, build, test, and launch CubeSats and other nanosatellites

- LinkedIn: Mike Galvin

- LinkedIn: Shannen Prindle

Want to learn more about our printers?

Learn how a Voltera dispensing system can help you prototype faster, waste less material, and protect your intellectual property.