Advance Electronics Additive Manufacturing with Voltera

INDUSTRY

Academia, Healthcare, Sensors, Smart Textiles, Sustainability, Wearables

APPLICATION

Bioelectronics

PRODUCT

V-One and NOVA

Highlights

For years, Gerd Grau, Associate Professor of Electrical Engineering and Director of the Electronics Additive Manufacturing Lab at York University used the V-One PCB printer. Then, in 2022, he was one of the first customers to upgrade to Voltera’s NOVA materials dispensing system.

Regularly utilized in their lab, NOVA has enabled Professor Grau and his team of researchers to publish a number of papers, such as:

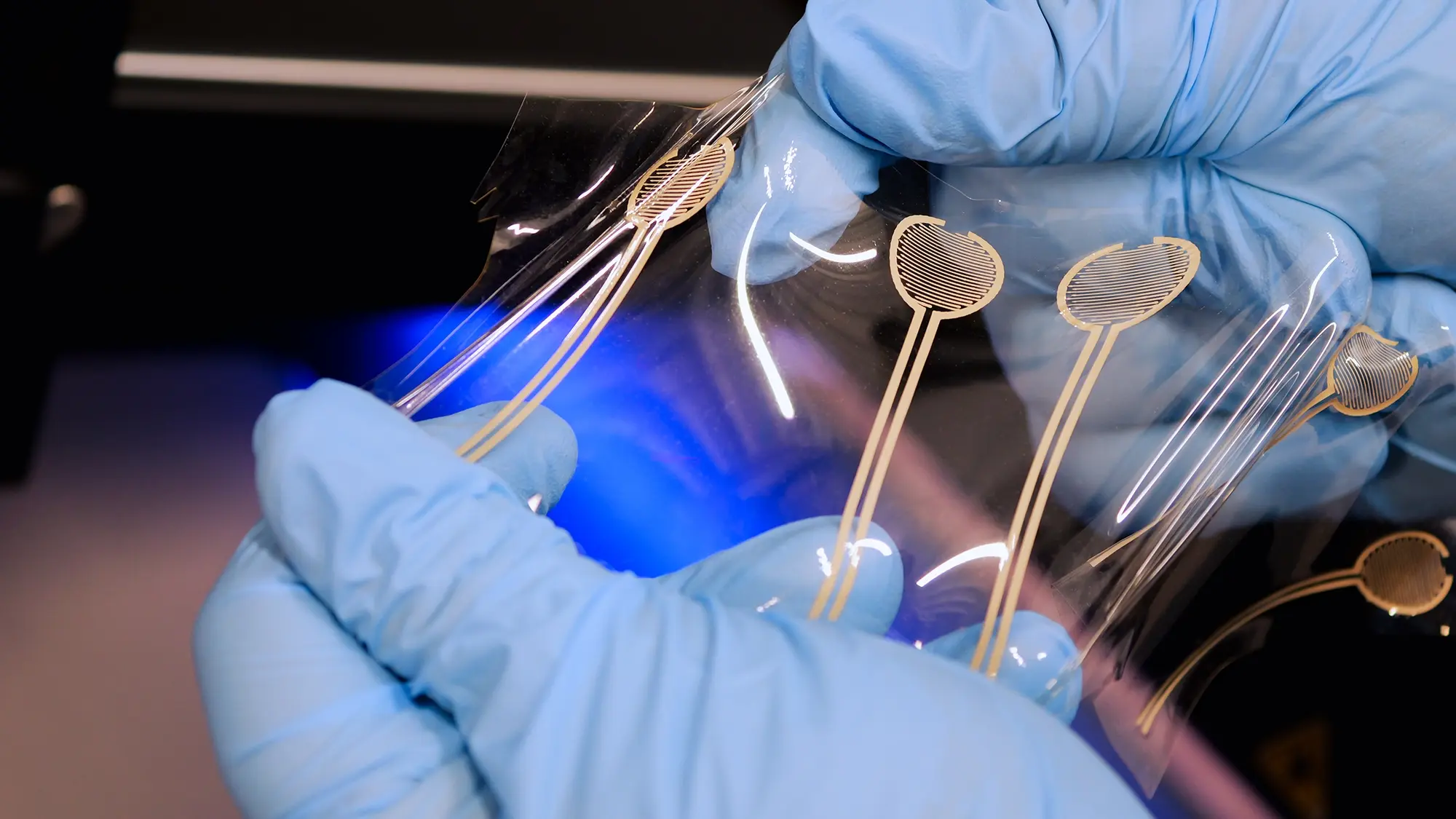

- Printed Tattoo Electrodes for Electrophysiological Signal Acquisition (2023, Yoland El-Hajj et al.)

- Low‐Roughness 3D‐Printed Surfaces by Ironing for the Integration with Printed Electronics (2024, Benno Neuhaus et al.)

- Ch Active Electrode with In-Channel Boosted CMRR for Distributed EEG Monitoring (2023, Alireza Dabbaghian et al.)

- …And more.

“I think where this sort of technology (NOVA) will shine is in applications that were not possible before. You shouldn't fight or try to compete with silicon chips or PCBs. You should try to make something that's impossible with those technologies.”- Gerd Grau, Director of the Electronics Additive Manufacturing Lab at York University

Working with V-One

Professor Grau and his team started using V-One in their research in 2019. At the time, they were researching projects that had applications in areas from stretchable electronics to printing electronics directly onto carbon fiber composites.

While V-One was getting the job done, it required a lot of workarounds for use with flexible, stretchable, and conformable applications because the machine was designed to print traditional, rigid PCBs.

Use cases like the ones being researched at York University were at the forefront of our minds when we began developing NOVA. We knew the next generation of electronics would have form factors that hadn’t yet been discovered.

Leveling up with NOVA

In October 2022, Voltera released the NOVA materials dispensing system. Avid V-One users who were conducting groundbreaking research and developing the electronics products of tomorrow suddenly had a new and innovative tool at their disposal for rapid prototyping and low volume manufacturing in the field of flexible hybrid electronics — wearables, biomedical sensors, antenna and RFID tags, and more.

Research Assistant, Yoland El-Hajj (pictured above), used NOVA in her research on Printed Tattoo Electrodes for Electrophysiological Signal Acquisition, as well as her paper comparing Inkjet and Extrusion Printed Silver Biomedical Tattoo Electrodes. More details on the latter project can be found on the Voltera blog.

“NOVA makes the printing process more efficient, so I am able to easily calibrate the materials I’m using and then print immediately. It also helps to specifically align the patterns I have onto a substrate. Overall, it has helped make the process more efficient and easier to change. It has significantly reduced the amount of time it takes to print the resulting pattern on the substrate compared to more traditional processes that involve the use of a mask or the use of laser cutting.”-Yoland El-Hajj, Research Assistant at York University

The NOVA difference

NOVA helps enable electronics that are conformal, stretchable, wearable, disposable, and/or biocompatible, to create devices that are lightweight, unobtrusive, and integrated directly into the structure of the world around us, rather than a board in a box.

When it comes to using NOVA in the E-AM Lab, Professor Grau believes it has offered a clear step up for their research — not only in terms of print quality, but also new features such as layer-to-layer alignment.

Additional resources

- Learn more: York University Electronics Additive Manufacturing Lab

- Voltera Blog: Printed Tattoo Electrodes — Cutting-Edge Biomedical Monitoring

- LinkedIn: Gerd Grau

- LinkedIn: Yoland El-Hajj

Want to learn more about our printers?

Learn how a Voltera dispensing system can help you prototype faster, waste less material, and protect your intellectual property.